Need a hand? Give us a call on +44(0)1923 691500

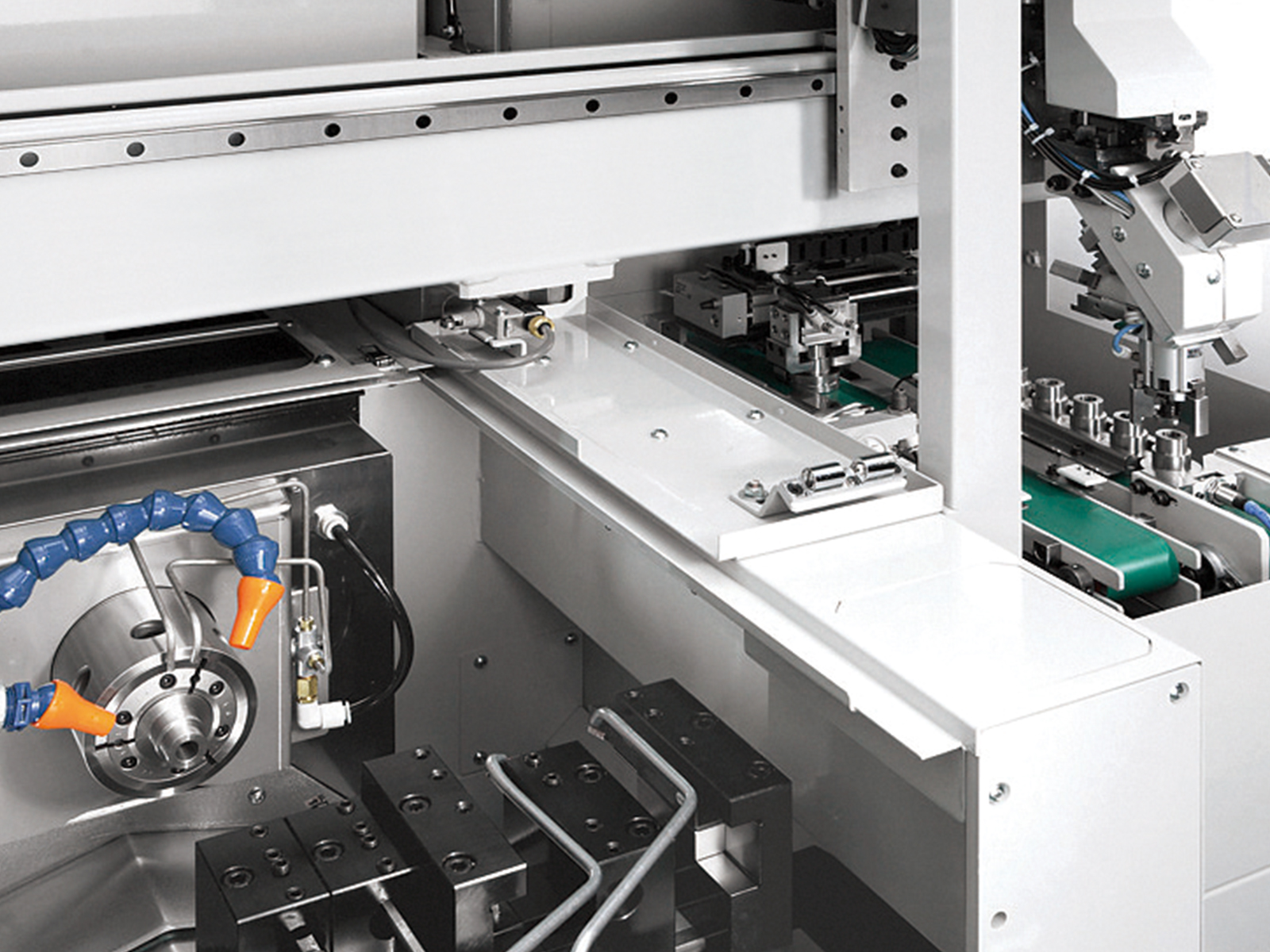

A compact design with a total machine width of 700 mm and a floor space requirement of 1.04m2 has made it possible to shorten production lines and improve factory space utilisation.

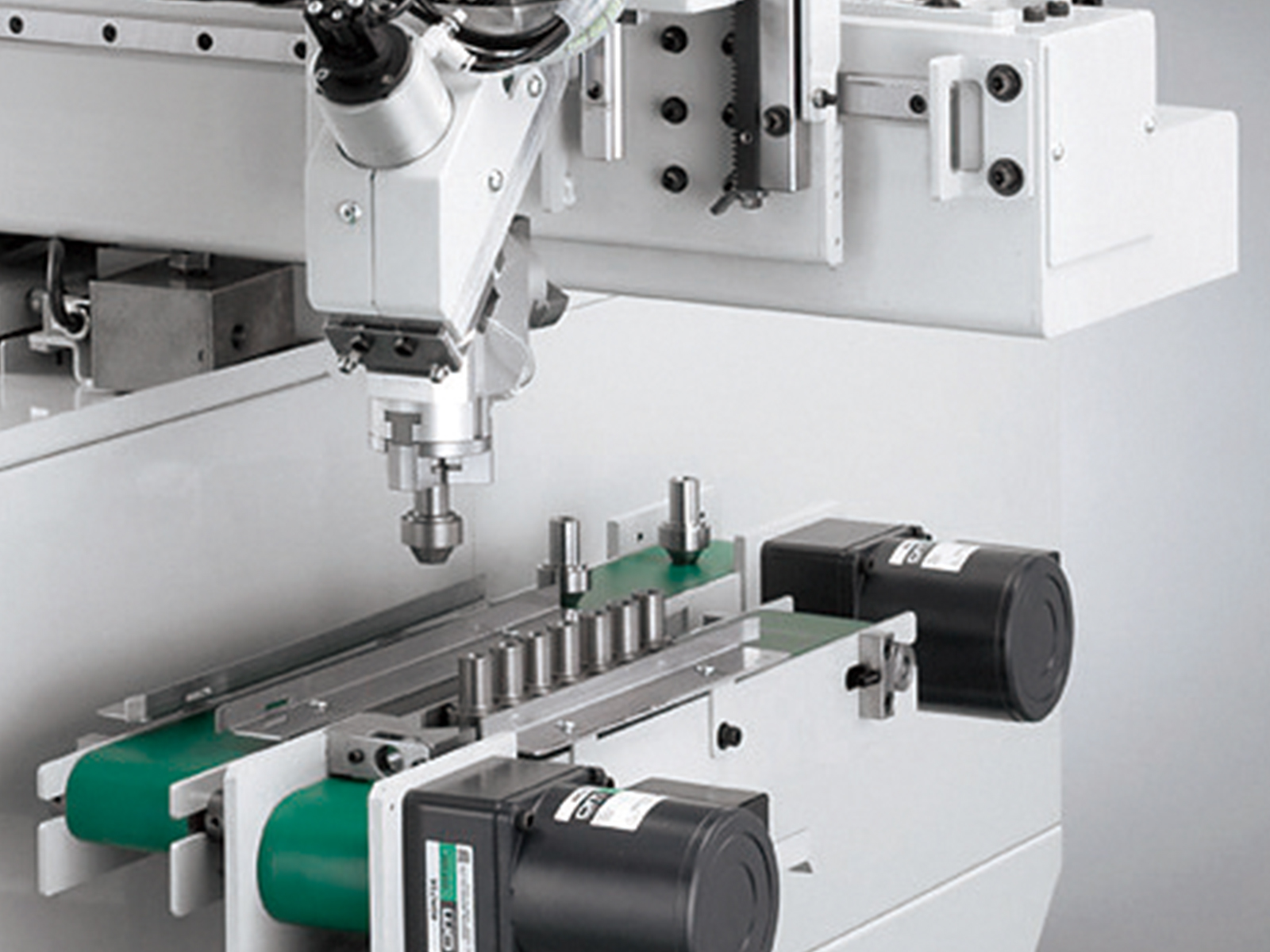

The incorporation of a high-speed gantry loader with a loading time of 3.5 seconds and a wide choice of infeed and outfeed devices allows stand-alone automation or integration with other processes.

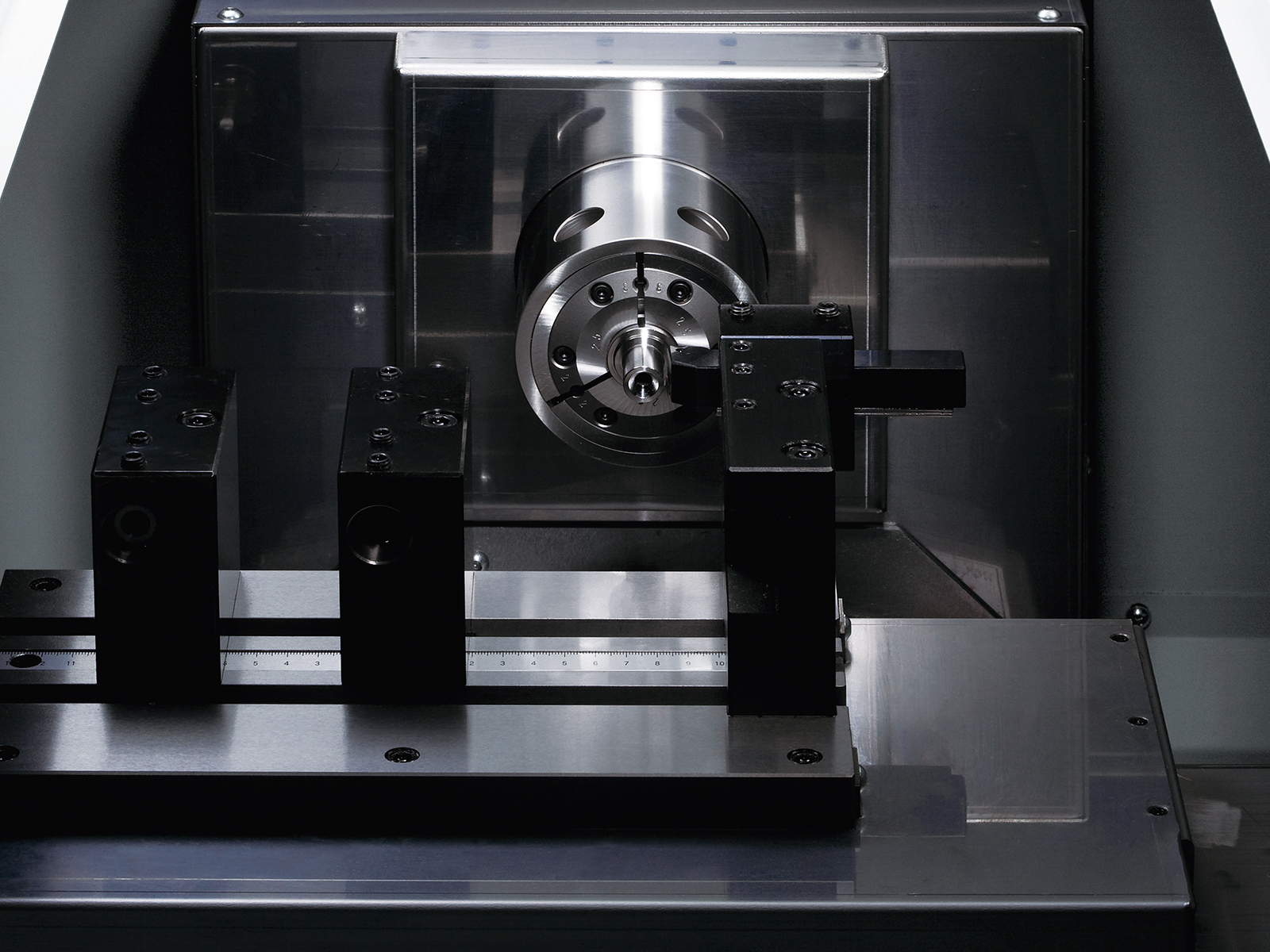

High-precision positioning and exceptional accuracy

A combination of a single slide construction, achieved using slides with excellent damping characteristics and a lubricating oil discharge control has increased follow-up performance for very small axis movement and has brought lost motion as close to zero as possible. Built-in spindles with forced cooling and built-in sensors give smooth rotation with low vibration thanks to beltless drive. This construction ensures outstanding accuracy and repeatability.

| Items | GN-3200 | |

|---|---|---|

| Machining Capacity and Chuck System | ||

| Power Chuck | Pneumatic | 3″(4″) Precision Chuck |

| Diaphragm Chuck | Pneumatic | 4″ |

| Maximum diameter of Collet Chuck | Stationary(with Pad) | ø35mm |

| Pull type(with Pad) | ø40mm | |

| Maximum Machining Length | 50mm | |

| Spindle | ||

| Spindle motor | 15min./cont. | 2.2/1.5 kW |

| Spindle Speed Range | 80 – 8,000 min-1 | |

| Turret | ||

| Type of Turret | Horizontal Linear Turret | |

| Shank Height of Square Turning Tool | □10mm, □12mm, □16mm | |

| Diameter of Drill Shank | ø20mm | |

| Slide Travel | X axis | 180mm |

| Z axis | 200mm | |

| Machine Dimensions | ||

| Machine Height | 1,600mm | |

| Spindle Center Height | 875mm | |

| Floor Space(Width × Length) | 700mm×1,460mm | |

| Machine Weight(machine only) | 1,500kg | |