Need a hand? Give us a call on +44(0)1923 691500

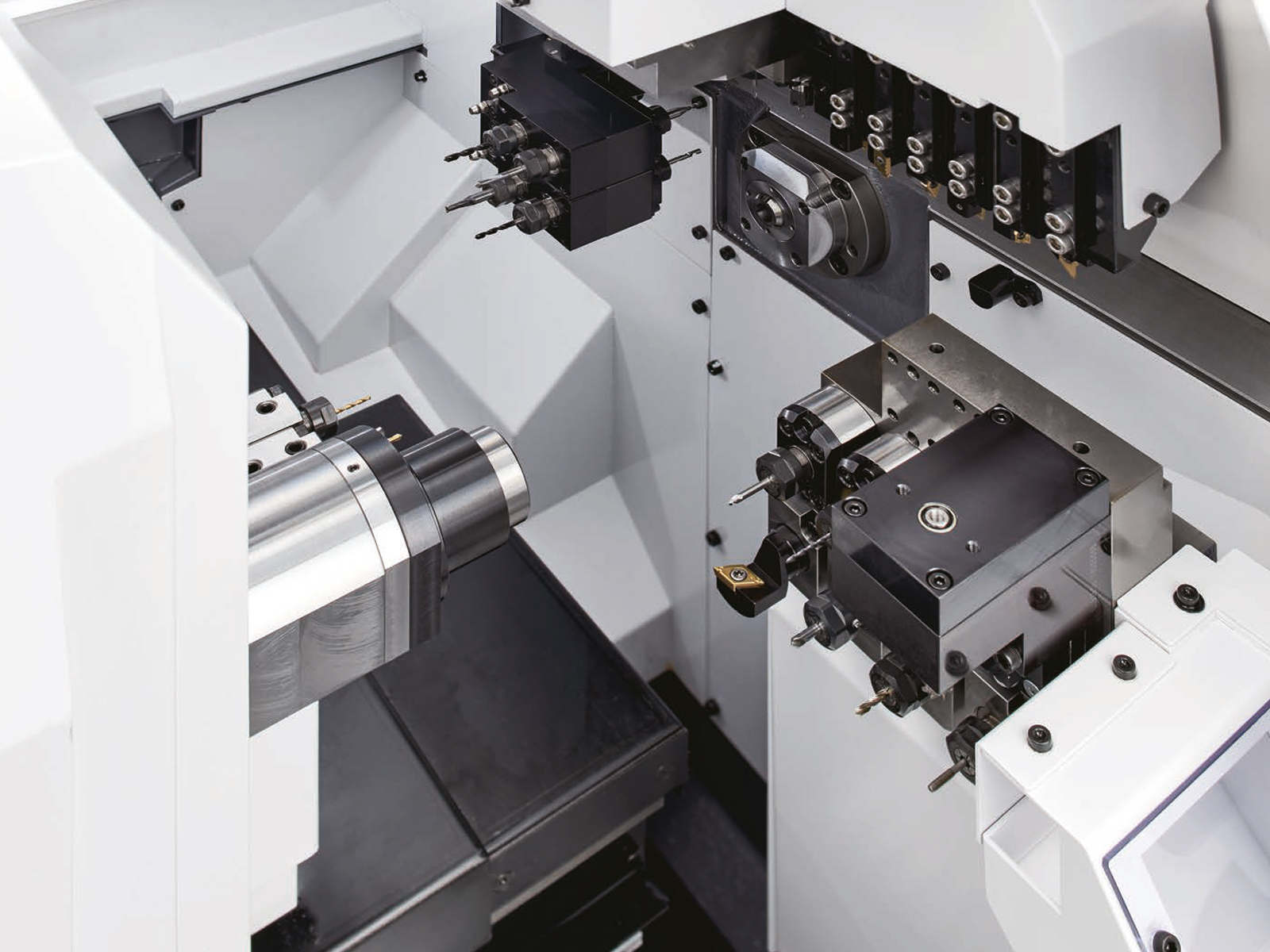

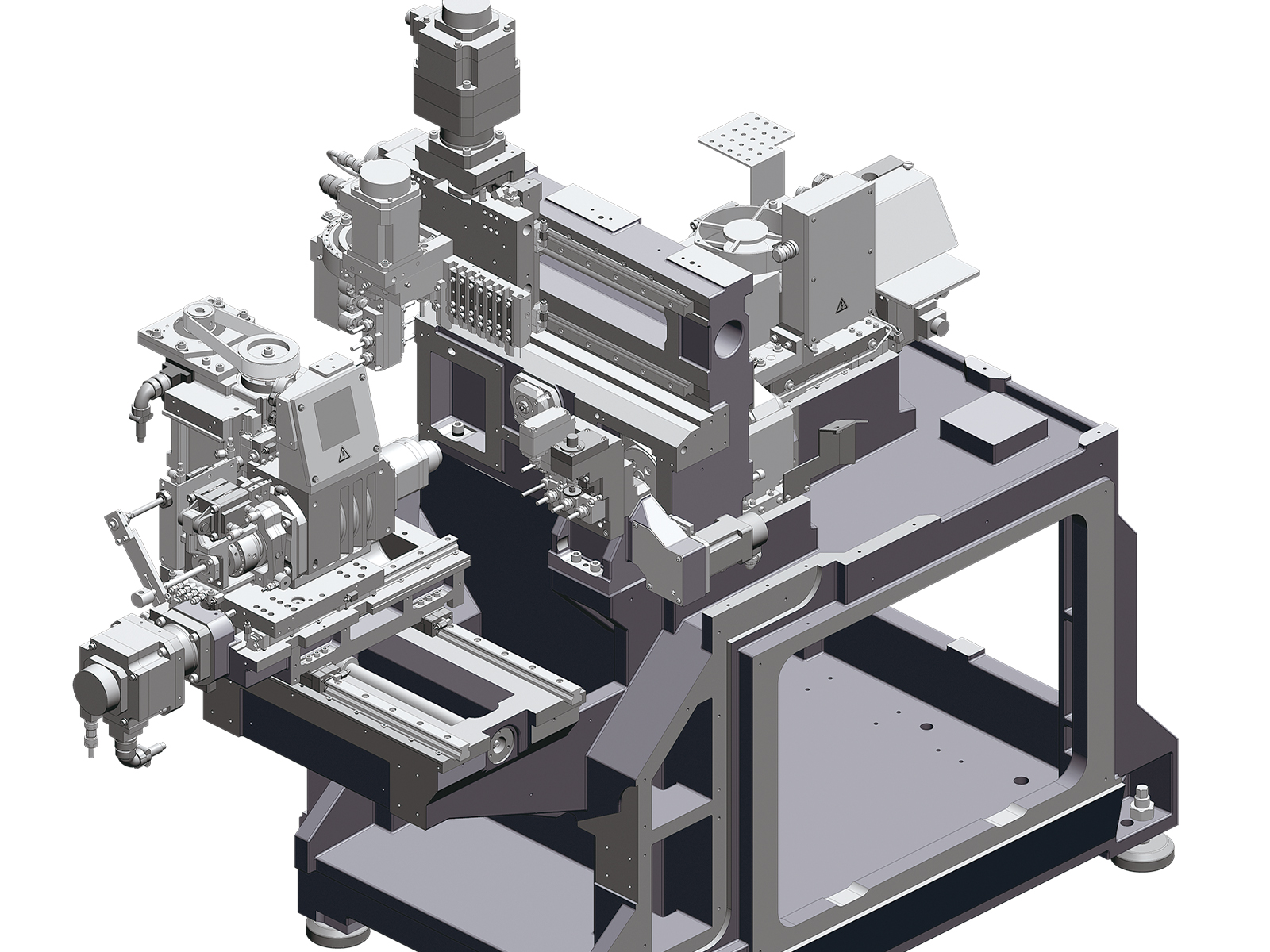

A modular tooling system has been adopted for the gang and back tool posts. The wide variety of tooling layouts available, such as “adjustable angle end-face spindle”, allows for angled hole drilling enhancing flexible machining. The addition of a Y2 axis to the back spindle strengthens back machining. This improves the degree of freedom for process allocation, and increases the maximum number of tools that can be installed to 38. Additionally, adoption of a built-in motor for the back spindle drive enables a maximum speed of 12,000 min-1. This reduces the acceleration/deceleration time to improve productivity. The machine is capable of handling 16 mm diameter bar with an expansion kit.

| Item | L12-X | |

|---|---|---|

| Maximum machining diameter | ø12mm/ ø16mm Option | |

| Maximum machining length | GB machine | 135mm/chuck |

| GBL machine | 30mm/chuck | |

| Maximum drilling diameter for main spindle | ø8mm | |

| Maximum tapping diameter for main spindle (tap,die) | M6 | |

| Main Spindle through-hole diameter | ø20mm | |

| Spindle speed | 15,000min-1 | |

| Maximum drilling diameter for gang rotary tool | ø5mm | |

| Maximum tapping diameter for gang rotary tool | M4 | |

| Gang rotary tool spindle speed | 10,000min-1 | |

| Maximum chuck diameter of back spindle | ø12mm | |

| Maximum protrusion length of the back spindle workpiece | 30mm | |

| Maximum drilling diameter in back machining process | ø6mm | |

| Maximum tapping diameter in back machining process | M5 | |

| Back spindle speed | 10,000min-1 | |

| Number of tools to be mounted | Max.27 | |

| Tool size | Turning tool | □10mm |

| Sleeve | ø19.05mm | |

| Rapid feed rate | All axis | 35m/min |

| Motors | For spindle drive | 2.2/3.7kW |

| For tool spindle drive | 0.75kW | |

| For back spindle drive | 0.4/0.75kW | |

| For cutting coolant oil | 0.25kW | |

| Input power capacity | 8kVA | |

| Center height | 1,000mm | |

| Weight | 1,700kg | |

| For rotary tool drive of Back tool post | 0.5kW | |

| Maximum drilling diameter for back tool post rotary tool | ø5mm | |

| Maximum tapping diameter for back tool post rotary tool | M4 | |

| Rotary tool spindle speed of back tool post | 9,000min-1 | |