See what's happening at Citizen Machinery UK.

13/ 01/ 21

Citizen Sets Up Dedicated Solution Centre

Citizen Machinery UK, which supplies Cincom sliding-head and Miyano fixed-head turn-mill centres into the British and Irish markets, has been providing manufacturing solutions to OEMs and subcontractors in their supply…

05/ 01/ 21

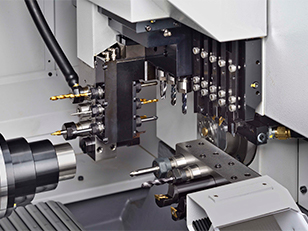

Large-capacity Y-Axis Lathe

Components are becoming more and more complex and drawing tolerances ever tighter. The ability of live turret tooling in a CNC mill-turn centre to move in the Y axis as…

14/ 12/ 20

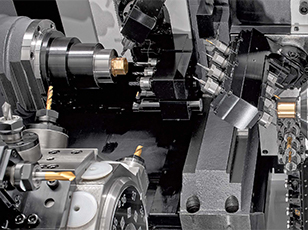

Citizen Machinery Upgrades Three CNC Sliding Head Turning Centres

Japanese CNC mill-turn centre manufacturer, Citizen Machinery, has announced improvements to three of its Cincom sliding-head models, all designed to shorten cycle times and raise productivity when producing components from…

17/ 11/ 20

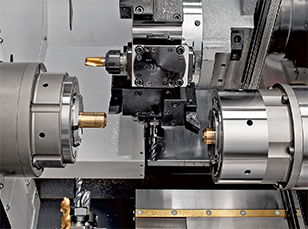

New Turn-mill Centre with Two Y-Axis Turrets

Complex components up to 65 mm in diameter may be turned and milled from bar on a new Miyano fixed-head lathe launched by Citizen Machinery UK. The 8-tonne BNE65-MYY is…

08/ 06/ 20

Latest Citizen CNC Sliding-head Lathe Upgraded with Chip Control Software

When turning long-chipping malleable materials, Citizen’s low frequency vibration (LFV) software fragments swarf into manageable chip sizes, whereas normally it would become a stringy bird’s nest entangled around the tool…

20/ 05/ 20

Contract Machinist Re-purposes Three-quarters of it’s Capacity for Ventilator Component Production

Subcontractor Unicut Precision, Welwyn Garden City, is no stranger to producing large quantities of components, one million items being shipped to customers in the UK and overseas in a typical…

06/ 05/ 20

Advanced Chipbreaking Technology Helps Ventilator Challenge

Like most turned parts subcontractors, Sub CNC Precision uses its 14 twin-spindle, multi-axis bar autos, in this case all from Citizen Machinery UK, to turn-mill parts in one hit from…

22/ 04/ 20

Motivational Time has united Manufacturing Industry

In the opinion of Citizen Machinery UK’s managing director Edward James, the Covid-19 pandemic has united the whole of the manufacturing sector to an extent never seen before in terms…

30/ 03/ 20

Five subcontractors respond to call for more ventilators by ordering seven Sliding-head Lathes in a fortnight

Edward James, Managing Director of sliding- and fixed-head lathe supplier Citizen Machinery UK, posted on social media on 16th March 2020 that the company is continuing to operate under the…